St. Petersburg, Russia

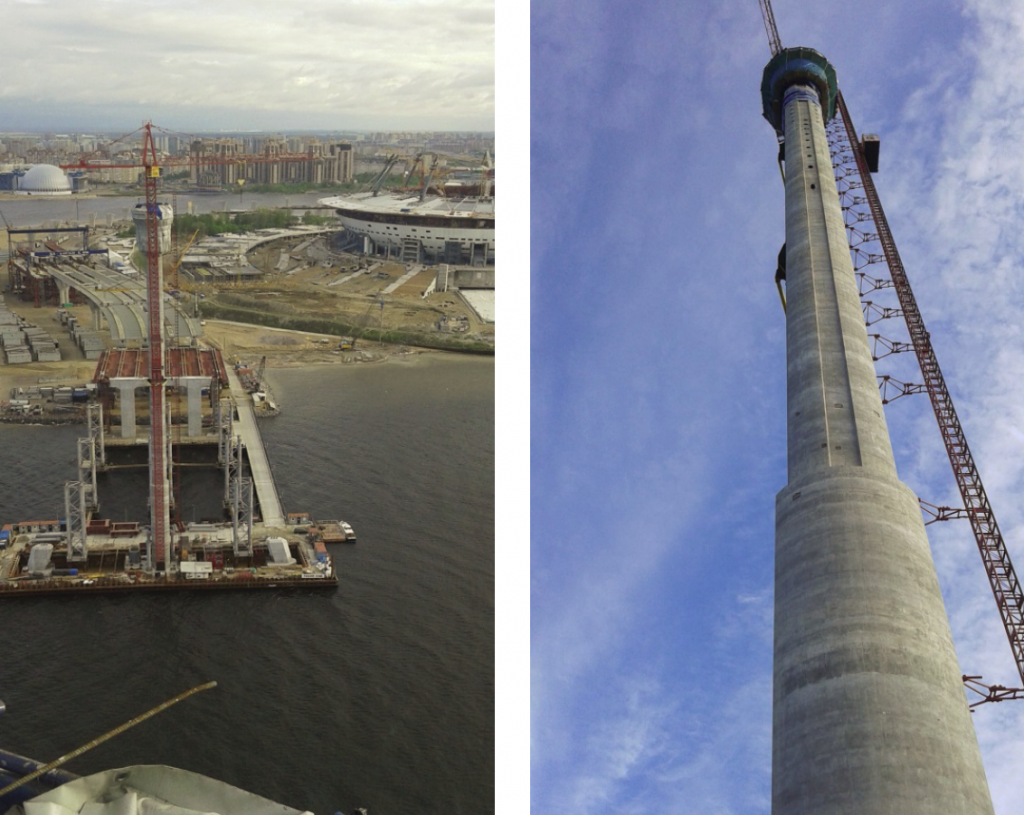

Pictured here are the bridge pylons for the Petrovsky Fairway cable-stayed bridge, which is a crucial link in the St. Petersburg Western High Speed Diameter Project. This is the largest PPP road construction project in the world today and the first urban high-speed toll motorway in Russia.

Elba Yaritim Sondazh Inshaat, the general contractor on this project, hired Gleitbau GmbH to slipform the two bridge pylons. The pylons are approximately 114 m tall with outside dimensions of roughly 5.0 m x 6.0 m per leg. The pylons were completed in 2014. Slipforming was chosen because of the speed of construction and the resulting structural durability, as the towers have no construction joints or form-tie holes.

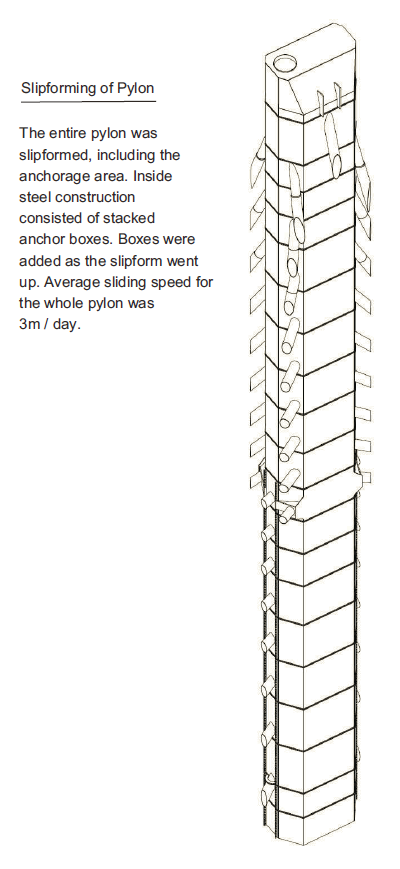

The cable anchorage area required the installation of welded steel boxes, which nowadays is the preferred method for defining the intricate stay pipe and bearing plate geometry for each cable.

The slipform was stopped at the underside of the first welded box, to insert steel supports into the wet concrete. These supports were then used for leveling and orienting the box in relation to the bridge.

At that point, the inside form was abandoned and slipforming continued with the outside form only, which ran flush with the ends of the stay pipes. These pipes were cut at compound angles to match the concrete surface.

As the slipform climbed, steel boxes were added. Bolts were used initially for connecting and adjusting the boxes, followed by final welding.

This particular design anchored the stay cables inside the tower. No cable saddles were used. The entire pylon was slipformed at an average speed of 3m / day, including the anchorage area.

Gleitbau GmbH is a leading slipform contractor with projects all over the world, including North America. The company was formed in 1961 and completes between 80 – 100 slipform projects every year. The scope of work normally includes the supply of custom slipform equipment, engineering, geometry control and supervision of the slipforming operation. For more information, please contact Michael Veegh.