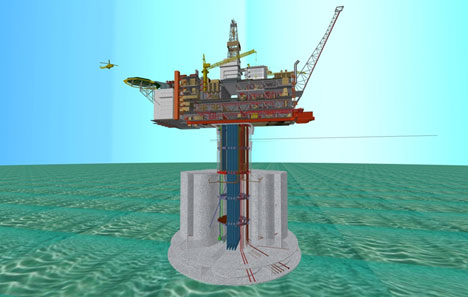

Hebron Gravity Based Structure

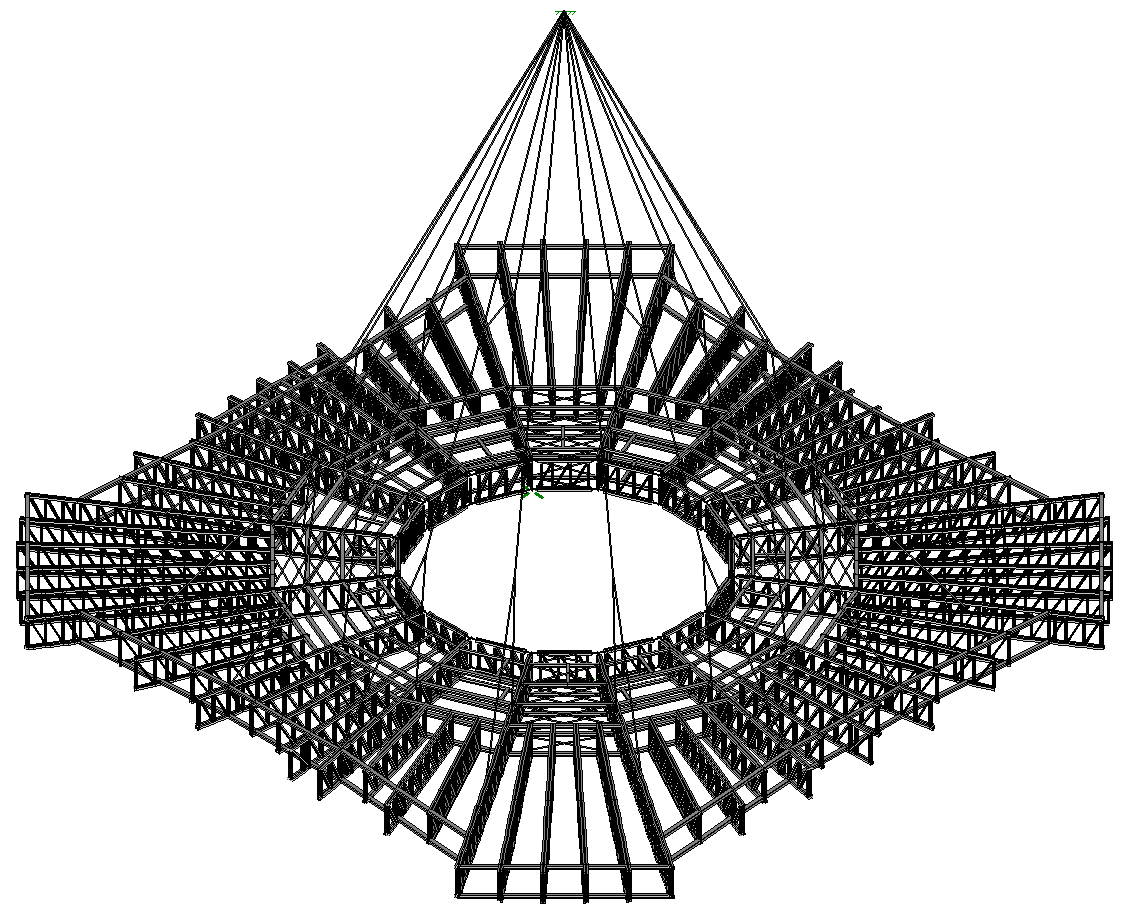

Newfoundland, Canada. As the year draws to a close, the KKC project team is making preparations for slipforming the main shaft of the Hebron GBS. This 35 m diameter shaft varies in cross-section from round at the bottom to approximately square on top. Thus, a highly specialized slipform system is required. Key to this system is the radial truss assembly seen below. It allows the slipform yokes and forms to move transversely as they glide upwards. The final result is the unique shape of the main shaft. This shape minimizes the drag below the waterline, but also offers a solid, square support on top, for the platform superstructure.

The slipform truss system being lowered onto temporary supports on top of the crude oil storage tanks in preparation for slipforming the main shaft, which varies in cross-section from round to square.

Slipforming such variable cross-sections represents a quantum leap in slipform technology. This technology was developed by Gleitbau GmbH, the only company in the world currently offering this capability. These systems are extensively engineered, as the truss assembly can weigh up to 200 tons.