Shin Seoncheong, South Korea – Tapered Rectangular Chimney

Global Chimneys Co. Ltd. hired Gleitbau GmbH of Salzburg Austria, to slipform this new chimney structure. The sliding operation was performed during 2017. The tapered rectangular shape makes for a unique and spectacular tower-like structure, made possible by the latest advances in slipform technology. The overall height is 148 m and the base dimensions of 20 m x 20 m taper off to 12 m x 12 m at the top. The wall thickness reduces from 0.90 m at the bottom to 0.35 m at the top.

While this particular structure is a chimney, its shape could equally be applied to a tall bridge pier, especially in regions with high seismic activity. The tapered shape would increase the flexural stiffness of such a pier, reduce transverse superstructure deflections and enhance the dynamic performance of the overall bridge. Slipforming is the only building method that can economically produce such a tapered, rectangular shape. The technology was developed and perfected for the slip form construction of offshore gravity base structures and then extended to include almost any kind of vertical concrete structure.

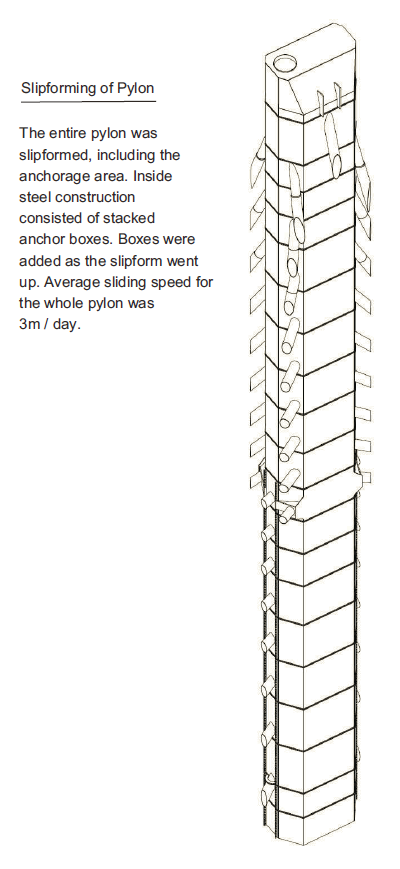

Some basic drawings about the slip form system of construction can be found here. Slipforming has proven to be a very dynamic and capable technology, rapidly adapting to changing market needs and able to create structures that were unthinkable just a few years ago.

Gleitbau GmbH is a leading slipform contractor in North America and around the world, executing more than 100 slipform projects per year. The company was founded in 1961 and became an industry leader during the 1970s and 1980s through its offshore work in the North Sea. Gleitbau GBG typically supplies the slipform system, engineering, concrete mix design, geometry control and technical supervision, mostly to general contractors. Heavy lifting services are also provided, many times in conjunction with slipforming. For more information, please contact Michael Veegh.